With over 20 years experience, we look for solutions not just problems.

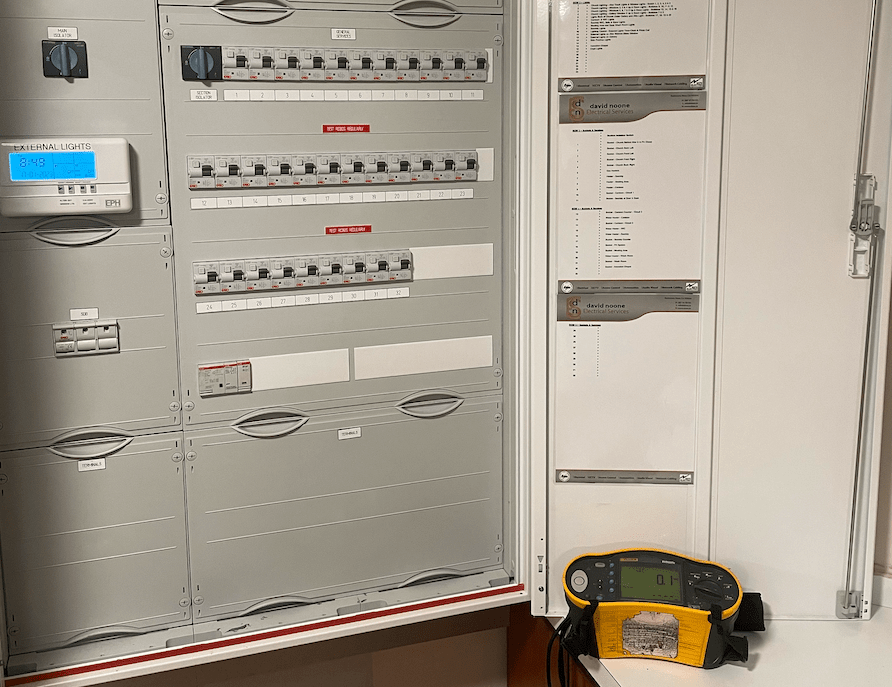

ETCI Periodic Inspection Reports (PIR)

All electrical installations deteriorate with age and use. They should therefore be inspected and tested at regular intervals to check whether they are in a satisfactory condition for continued use. Such safety checks are commonly referred to as ‘ETCI periodic inspection and testing’.

A periodic inspection will:

- Reveal if any of your electrical circuits or equipment are overloaded

- Find any potential electric shock risks and fire hazards

- Identify any defective electrical work

- Highlight any lack of earthing or bonding

- Compliance with the National Rules for Electrical Installations ET101

There are many reasons why the inspection and testing of all electrical systems is of the utmost importance.

First and foremost there is legislation which requires certain electrical installations are maintained to safety standards, meaning they must be periodically inspected and tested. As well as the requirement to be compliant with ET101, you may also find that other organisations such as the local authority or your insurance agents will require periodic inspection and testing of all your electrical installations by a professional electrician.

Additionally, electrical systems can deteriorate over time due to damage, wear and tear, corrosion, excessive electrical loading or environmental issues. This means they could be working less competently and cost you more. More importantly, they could be dangerous and put the safety of your congregation and visitors at risk.

Periodic inspections and testing should only be carried out by a Registered Electrical Contractor (REC).

The inspection takes into account all the relevant circumstances and checks on:

The adequacy of earthing and bonding. The suitability of the switchgear and control gear.

For example, an old fusebox with a wooden back, cast-iron switches, or a mixture of both will need replacing. The serviceability of switches, sockets and lighting fittings. Items that may need replacing include: older round-pin sockets, round light switches, cables with fabric coating hanging from ceiling roses to light fittings, black switches and sockets mounted in skirting boards. The type of wiring system and its condition. For example, cables coated in black rubber were phased out in the 1960s.

Likewise cables coated in lead or fabric are even older and may well need replacing (modern cables use longer-lasting pvc insulation). Sockets that may be used to supply portable electrical equipment for use outdoors, making sure they are protected by a suitable residual current device (RCD). The presence of adequate identification and notices. The extent of any wear and tear, damage or other deterioration. Any changes in the use of the premises that have led to, or may lead to, unsafe conditions. We will then issue the report along with the test results detailing any observed damage, deterioration, defects, dangerous conditions, and any non-compliance’s.

If anything dangerous or potentially dangerous is found, we will list it as part of the remedial action that needs to be carried out with a rating of 1 to 4 as to how serious the defect is and what action is required to rectify it.

Types of Inspection and Testing to be done during formal Inspection & Testing

The following non-exhaustive list indicates the types of inspection and tests that are necessary to complete the periodic inspection and testing of an installation:

- General appraisal of the installation by a competent person to assess the physical condition of the installation and its suitability for its environment

- Continuity of the protective conductors and of the main supplementary equipotential bonding

- Continuity of conductors in ring final circuits

- Resistance of protective conductor

- Insulation resistance of the electrical installation

- Polarity

- Fault Loop Impedance test

- Verification of Operation of RCDs including the tripping times of all RCDs

DNES electricians are fully conversant with the requirements of the ETCI Wiring Regulations (ET101) and are qualified to undertake testing all types of industrial, commercial and domestic electrical installations, including bespoke solutions for churches.

We can create a schedule of periodic testing and inspection for the electrical systems within your church and will ensure our work is carried out in a manner which minimises any impact on your daily activities. We can also be called upon to advise you when any additional testing may be required, for instance if you change the use of your premises, if interim damage is suspected or if there is any significant change in the electrical loading of the installation.

For your convenience, we process all inspections and tests quickly and customers are informed as soon as possible of the results. This ensures there are no delays in addressing faults or deviations from regulations or quality standards. All certification is held securely on our database to allow for any future tracking of the inspection processes.

Should any repair works be required, we’ll happily provide you with a quotation for any rectification work and will aim to offer a repair service that is professional, timely and cost-effective.